DXN Company

With its headquarters in Malaysia, DXN lives by certain guiding

principles in its day to day operation, these are: "One Dragon", "One World One

Market" and "One Mind".

The first and market leader Ganoderma Network Marketing company

DXN is dedicated in following through with all

aspects of its business model from Cultivation and Processing all the way to

the actual marketing of its Ganoderma enriched products direct to its

consumers. This process has granted DXN global acclaim for its state of

the art management system, research and development as well as the highest of

quality products on the market today.

DXN is the 15th biggest direct selling company in the world.

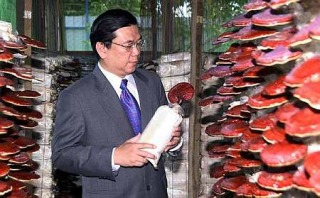

Dato' dr. Lim Siow Jin, founder of DXN

DXN was founded by Dato' Dr. Lim Siow Jin, a graduate from the prestigious Indian Institute of Technology, in 1993. His deep interest on the benefits of mushrooms on human health particularly led him to the wonders of Ganoderma. This commences his quest to utilize the fullest potential of Ganoderma or Lingzhi, considered as the King of Herbs, and similarly benefit those who want to keep healthy.

Concept

"One Dragon"

The entire process - cultivation, processing and marketing is solely done by the Company under strict quality control.

"One World One Market"

Each and every distributor enjoys worldwide bonus with single membership.

"One Mind"

The company and the distributors single-mindedly concentrate on doing DXN business.

DXN ganoderma plantation

The

DXN ganoderma plantation covers an area of 70 hectares. This is the

largest plantation in Malaysia and the first to receive MS ISO 14001:

2004 certification from Lloyd's Quality Assurance Company in July 2000.

This certification also ensures that all ganoderma cultivation processes

comply with MS ISO14001: 2004 and meet all requirements of the Ministry

of the Environment.

November 2007, the Ministry of Agriculture accredited the DXN Lingzhi Plantation to the Malaysian Bioservice, which means it meets the MS1529: 2001 standard and the requirements of the Certified Organic Plantation.

The DXN pharmaceutical factory occupies and area of over 34,000 square meters and is equipped with state of the art technologies for the processing of the Ganoderma. This factory if the first of its kind in Malaysia that has been granted the TGA (Therapeutic Goods Administration) certification from the ministry of health and Aging Australia and is also accredited with MS ISO 9001:2000 certifications from the Lloyd's Register of Quality assurance since September of 1999. It is also amongst the first companies to receive the GMP (Good Manufacturing Practice) certification from the national Pharmaceutical control bureau and the ministry of health in Malaysia.

The two DXN coffee processing factories have a total manufacturing area of over 42,000 square meters which include modern facilities for the manufacturing of complete line of food and beverage ranges.

DXN's newly established manufacturing facility which houses it's Cosmetic, Juice and Enzyme factories have all been accredited the GMP certificate from the national pharmaceutical control board and the ministry of health in 2007. The factory and its accumulated administrative offices have a total area of over 70,000 square meters.

DXN Marketing is the first MLM company in the world to launch its "One World, One Market" concept which enables distributors from any country to directly sponsor new distributors either locally or internationally. DXN is also Malaysia's leading MLM exporter.

Research and Development is DXN's mission when it comes to securing the highest quality for all its products. The concentrated efforts of DXN in research and development have continuously led the company to manufacture products with highest international standard and as natural to its origin as possible.

On July 17, 2006, the Laboratory Department of DXN Holdings Bhd. has been accorded MS ISO/IEC 17025 Certificate of Accreditation for its technical competence, defined scope and operation of a laboratory quality management system.

Research and development also emphasizes DXN´s long term commitment of placing top priority on environmentally-friendly practices and human health in every stage of production.

Why DXN Ganoderma is unique?

- Malaysia has more than 200 species of edible ganoderma.

- After many years of research by Datuk Dr Lim, only 6 species of RED mushrooms are being selected, because they give the best therapeutic effects. DXN ganoderma is a combination of these 6 species.

- There are more than 200 bioactive elements in Ganoderma. However Ganoderma researchers identified which ingredients have the most medicinal values. These ingredients are Polysaccharides, Triterpenes, Adenosine, Organic Germanium. All these active ingredients are found in the spores of Ganoderma. The active ingredients are sensitive to heat. If the method of extracting the spores from the fruit body is not right, medicinal values of ganoderma can be affected.

- Datuk Dr Lim has the knowledge and technology to preserve the potency of DXN Ganoderma. Therefore DXN develops own technology, does not depend on others for the development of the company.

- First DXN needs to ensure Ganoderma plant is healthy, optimum production of spores can be maintained. DXN uses tissues culture method. By using this method, exact duplication of the healthy mother plant can be preserved and the good healthy ganoderma plant can be repeatedly reproduced. By using this method, the quality control of high quality Ganoderma is possible.

- DXN uses 100% organic cultivation method, using saw dust and brown rice powder.

- To ensure the mushrooms are not contaminated, DXN uses hanging method, so that they do not touch the floor.

- DXN Ganoderma is harvested when 3 months old. Time of harvest is very important. In nature Ganoderma disperse the spores after 3 months for reproduction. If the time of harvest is not controlled, ganoderma may left with little or no spores, the medicinal values of ganoderma can be badly affected.

- DXN ensures all the important elements in the mushroom is not destroyed, no heat is applied to dehydrate the harvested mushrooms. DXN uses cold method to freeze dry the mushrooms. This is a special technology owned by DXN.

- Then fibre separation can take place when the ganoderma is dried. The dried ganoderma is being crushed to remove the fibre and the spores are extracted from the fruit body. The total concentration is 20:1

- After the spores are extracted, theys are treated with ultra violet ray to enhance the therapeutic effect of Ganoderma.

- The final stage is micro powderation. The spores have hard cover eternally. If the spores' hard cover is not crushed, the spores will not give therapeutic effect as our gastro-intestinal tract cannot absorb the nutrients. DXN uses her own developed technology. The spores are poured into the machine with 7 levels of spinning wheels. When the spores enter the 1st level, some of the hard cover of the spores is crushed. When the crushed spores are lighter, they enter into 2nd level, 3rd level and so on. When the spores reach the 7th level, the spores are reduced into micro size.

- All bioactive ingredients are conserved throughout the special technology of DXN.

DXN products

100% natural raw materials. Quality of DXN products is given priority at each step of production. International standards ISO 14001, ISO 9001, and TGA Recognitions.

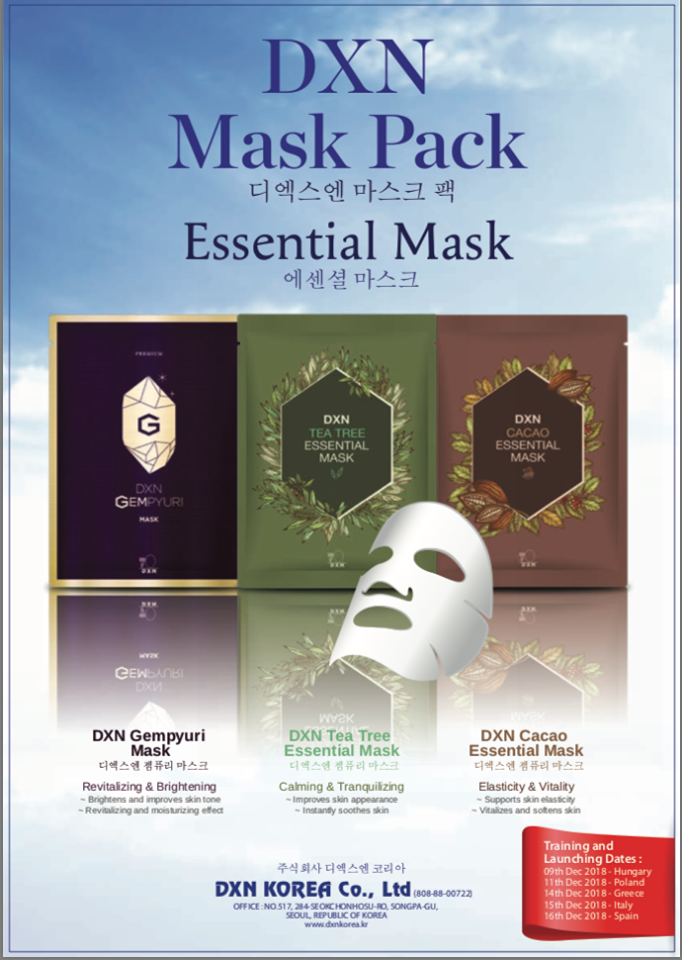

Ckin Care - Korea Series